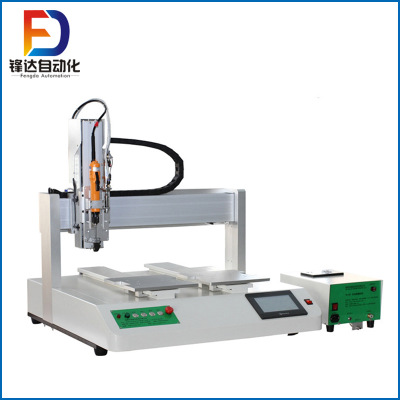

The biggest advantage of this type of automatic locking screw machine is flexibility and efficiency. According to the set coordinates, the machine will automatically complete the product lock payment. The z-axis can be installed at most 6 for simultaneous lock payment, which greatly improves production efficiency. Change the product, just by modifying the lock point coordinates can be. The operation is very simple. In today's rapidly changing product era, the investment of fixed assets can be greatly saved. Fd-8900 automatic locking screw machine, through the distribution system to distribute the screws and through the air pipe pressure to the screw to the lock mouth, through the manipulator according to the set of coordinates automatically complete the lock payment.

Advantages:

1. Good versatility. Small volume, can cooperate with the production line operation, change the product convenience.

2. High efficiency. A few electric batches work simultaneously, can replace many workers; For example, if you install 4 electric batching machine,

Lock multiple screws at one time to renew the lock, the machine can lock several products at once. The number of z-axis can be customized according to customer's requirement.

3. The Y-axis can be made into a double work position (i.e., double Y-axis) according to the need, and the operator can alternate the upper and lower materials.

4. Reduce the labor intensity of workers. The traditional manual placing screws and the alignment of the screw head require a lot of work time and energy.

5. High degree of automation. Simple operation, quick command of staff and debugging. A worker can manage several machines at the same time. Save labor.

6. The torque is accurate. Easy to adjust, ensure the lock quality.

7. Compared with the inhalation type, the blow air screw is delivered directly to the batch. It saves the time to get the screws back and forth, and is more efficient. More stable.

Performance:

Positioning accuracy: X,Y:+/-0.08mm Z: +/-0.01mm.

Operating speed: 500mm/ SEC (x-y)

Xili electric batch: it can be selected according to customer's requirement.

Torque: customer adjustable.

The handling of locking defective products: alarm lights and buzzer tips.

Parameters:

1. External dimension: high 730* long 783* width 693.

2. Rack: steel plate table, aluminum alloy frame.

3. Power supply: AC 220V 50HZ.

4. Ambient temperature: -20~40 degrees.

5. Power: 300W.

6. Host program control: dedicated controller.

7. Man-machine interface: special man-machine interface.

Scope of use:

1. Applicable screw range: m1-m6.

2. Used screw heads: cross, triangle, plum, hexagon, Y, etc.

3. Used screw surface treatment such as: nickel, clay pot, zinc plating, white zinc plating, copper plating, etc.

4. Used screw materials such as iron, copper, stainless steel etc.

5. Materials for locking screw products such as plastic, iron, aluminum, etc.

6. Full-automatic lock screw blowing machine is widely used in various industries, such as mobile phone, hard disk, keyboard and play.

Assembly of electronic processing plants such as LCD/LED module, communication equipment, electronics, toys and auto parts.